Basic Info.

Model NO.

SHC-3

Material

Mild Steel,Nylon Plus Fiber Glass PA66

Transport Package

Export Carton

Specification

Suspension clamp

Trademark

SMICO

Origin

China

HS Code

8536909000

Production Capacity

500, 000 PCS Per Month

Product Description

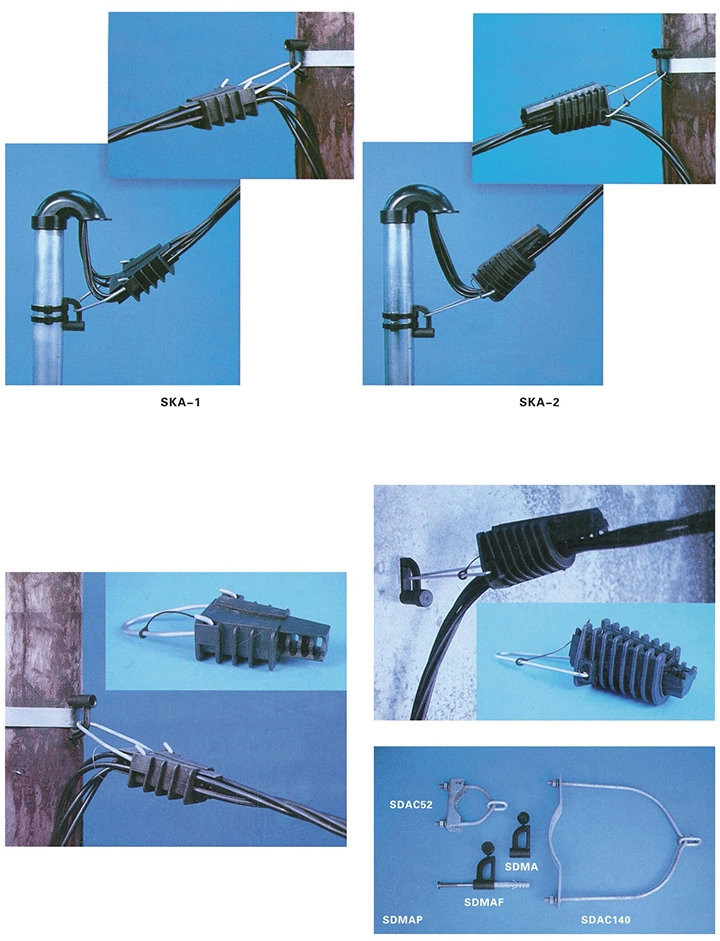

SHC-3 ABC Cable Aerial Electrical Fittings Suspension Connector

(Performance testing)

2.1 Mechanical performance:the grip force of the wire clamp is 1/10 bigger than the break force of the lead. It comply with GB2314-1997

2.2 Temperature rise performance: under the conditìon of big current, the temperature rise of connector is less than that of connection lead.

2.3 Heat circle performance:confirms to GB/T2317.3-2000,the beat circle trial standard for electric fitting.

2.4 Waterproof insulatìon performance:confirms to the relevant requirements in Part 2 of GB/TI3140.4-1998,

2.5 Resistance to corrosion performance: under the conditìon of SO, and salt fog, it can do three tìmes of fourteen days circle testìng.

2.6 Environmental aging performance:under the circumstance of ultraviolet, radiation, dry and moist, expose if with change of temperature and beat impulse for six weeks.

2.7 Fire-proof performance: insulation material of the connector withstands glowing filament test. Confirm to the requirements in Chapter4-1 0 of GBrr5169.4

Introduction

The suspension clamp is provided with black weather-resistant plastic coating of at least 1mm thickness to prevent the insulation of the phase conductors from chafing due to rubbing against the clamp.

Material

1.Body and Pressure Pad:weather resistant aluminum alloy.

2.Plastic protection:weather and UV-radiation resistant plastic.

3.Nuts,washers&Bolt:hot-dip galvanized steel.

Detail specification

| MODEL | CROSS-SECTION( mm2) |

| SHC-3 | 4X(50-70) |

(Performance testing)

2.1 Mechanical performance:the grip force of the wire clamp is 1/10 bigger than the break force of the lead. It comply with GB2314-1997

2.2 Temperature rise performance: under the conditìon of big current, the temperature rise of connector is less than that of connection lead.

2.3 Heat circle performance:confirms to GB/T2317.3-2000,the beat circle trial standard for electric fitting.

2.4 Waterproof insulatìon performance:confirms to the relevant requirements in Part 2 of GB/TI3140.4-1998,

2.5 Resistance to corrosion performance: under the conditìon of SO, and salt fog, it can do three tìmes of fourteen days circle testìng.

2.6 Environmental aging performance:under the circumstance of ultraviolet, radiation, dry and moist, expose if with change of temperature and beat impulse for six weeks.

2.7 Fire-proof performance: insulation material of the connector withstands glowing filament test. Confirm to the requirements in Chapter4-1 0 of GBrr5169.4