Basic Info.

Model NO.

Copper braided tape conductive tape Connects the g

Size

Large

Brand

Xincheng

Type

Braid

Plated

None or Tinned or Nickel

Cross Section

1.5-400mm2

Single Wire Diameter

0.05-0.3mm

Width

as Customers′ Demand

Length

as Customers′ Demand

Transport Package

Plywood Case

Specification

PIECE

Trademark

XINCHENG

Origin

China

Product Description

Quick Details:

Place of Origin: China Brand Name: XIN CHENG

Type: Braid

Application: grounding, for electrical connection, flexible connected wires, Electrostatic shielding, power, etc.

Material: C11000 copper, copper content more than 99.9% Conductor Type: Solid

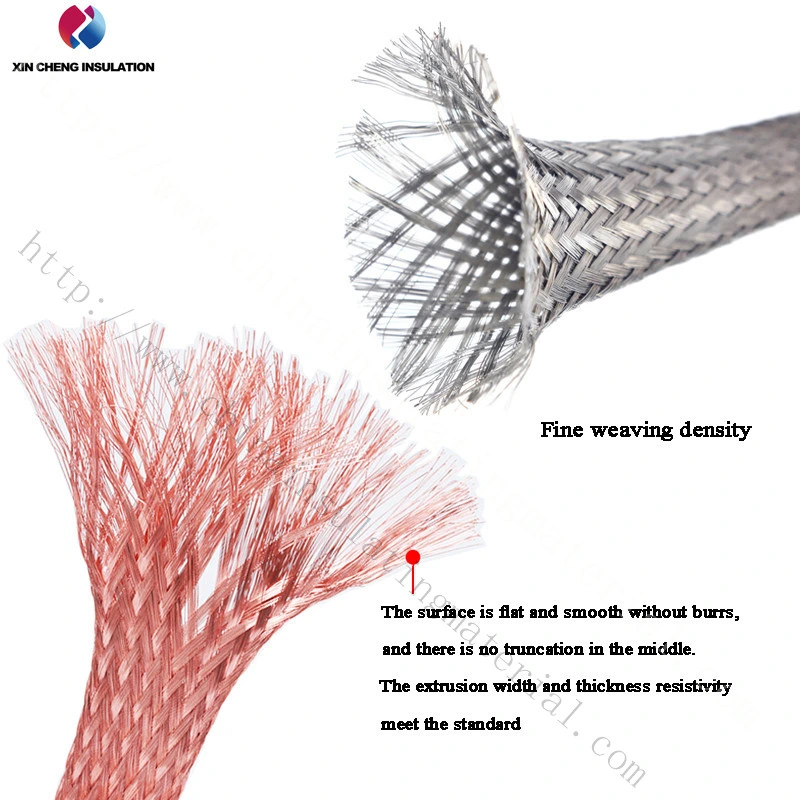

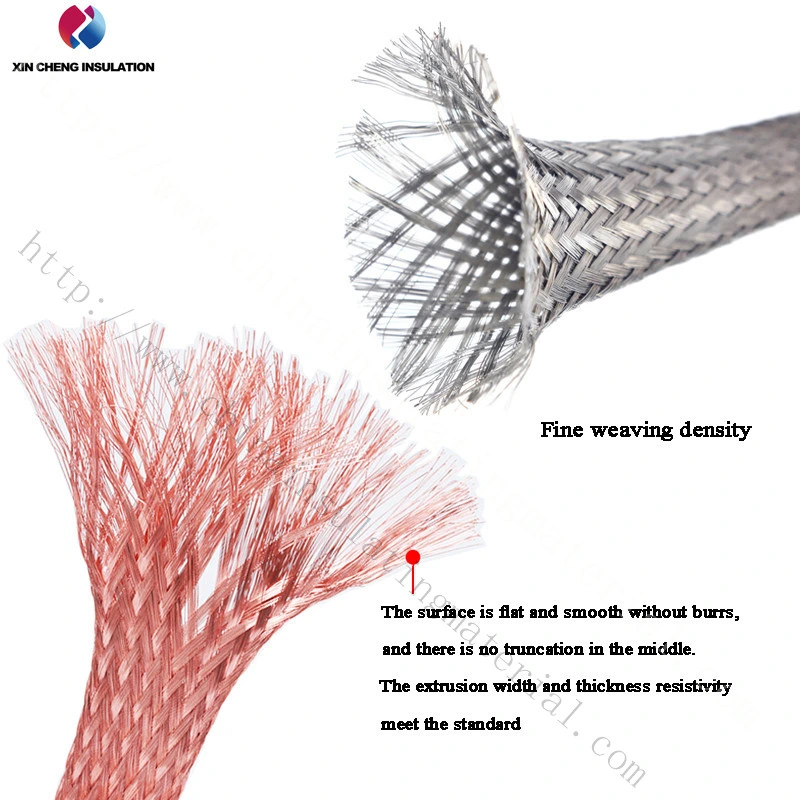

Insulation Material: none Feature: pure copper wire braided

plated: none or Tinned or nickel Cross section: 1.5-400mm2

Single wire diameter: 0.05-0.3mm Length: as customers' demand

Width : as customers' demand Number of sets (layers) : as customers' demand

Certificate: ISO9001; RoHS Standard: TZ/TZX(JB2572-79)

Product Description:

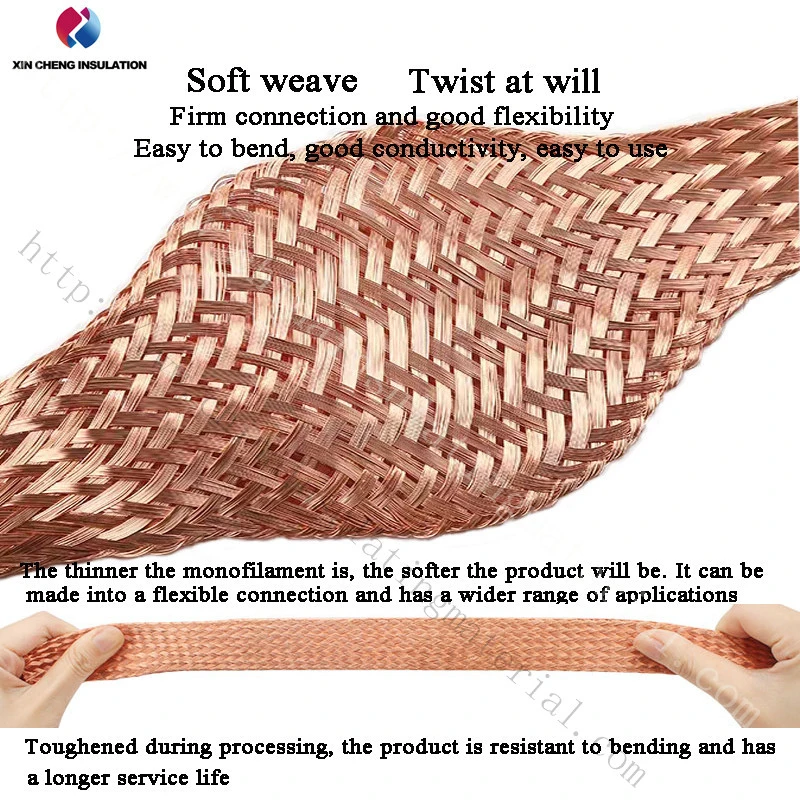

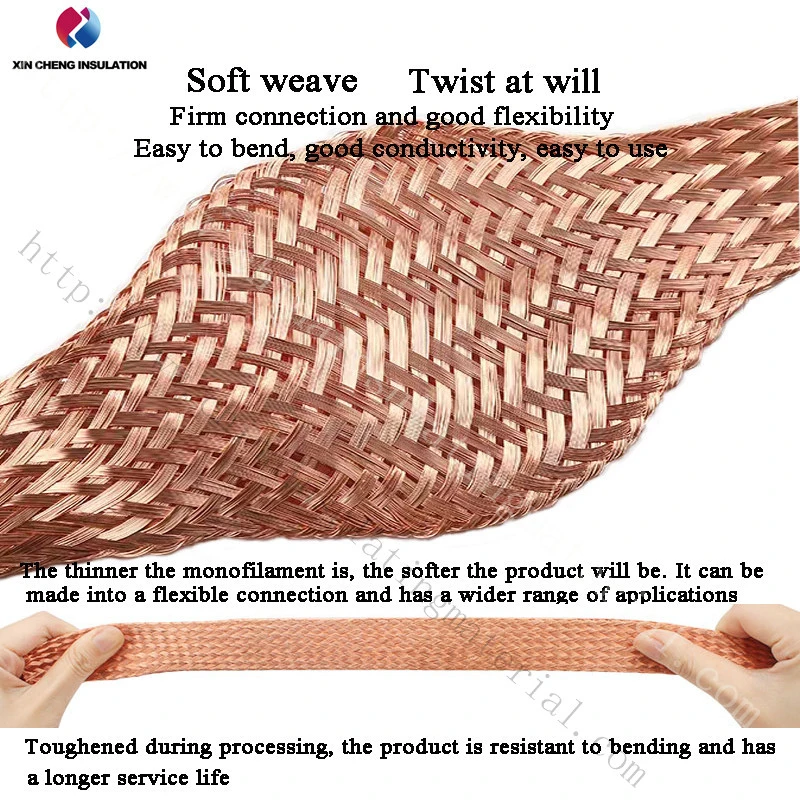

Copper Braided Grounding Strap is made by braiding a number of spindles (13,16,24,36,40,48,64,96) of best quality round copper wires (0.05,0.10,0.12,0.15,0.19,0.20,0.25mm) or soft tinned wires (0.05,0.10,0.12,0.15,0.19,0.20mm) to become single layer of multilayer type. It is used for the flexible conductor of electric installation, switch gear, electric furnace, storage battery, etc.

If you have any other special specifications, please provide drawings or samples, our company can customize the products according to your request.

The commonly used Single wire diameter: 0.05mm, 0.07mm, 0.10mm, 0.12mm, 0.127mm, 0.15mm, 0.2mm, 0.25mm, 0.254mm, 0.3mm etc.

Copper braided tape Material: red copper Surface treatment: tin/silver/nickel plating according to technical requirements Application: New energy electric vehicle battery copper soft connection is suitable for battery conduction, automobile, aerospace, mechanical and electrical equipment, medical equipment and other conductive fields. Product features: fire - proof, electric - conduction, pressure - proof, corrosion - proof, etc.

The tinned copper braided mesh tube is braided by multiple strands of tinned copper wire with a diameter of 0.05-0.30mm. It has flexibility, wear resistance, anti-electromagnetic interference of wires, and electrical conductivity, which can tighten wires of various irregular shapes. It can also remain soft in a wide temperature range, and its unique mesh shape has good heat dissipation.

Copper braid tape and flexible busbar connectors with termination for switchgear and control panels such as power interconnections, earth bonding leads, earth braid assemblies and flexible busbar assemblies for high current application

Application:

Copper braided tape is also widely used in transformer installation, soft connection of high and low voltage switchgear, vacuum electrical appliances, closed bus duct, generator and bus, rectifier equipment, rectifier cabinet and disconnector, automobile, electric locomotive, industrial electric furnace, mining explosion-proof electrical appliances, generator set, carbon brush wire and connection between buses. It can improve the conductivity, adjust the equipment installation error, and play the role of (shock absorption) work compensation, convenient test and equipment maintenance.

Technical Performance:

Technical Performance:

Copper braid flexible connector Current Ratings:

Specifications:

Remarks: Cross section: 1.5-400mm2

Single wire diameter: 0.05-0.3mm,Length: as customers' demand

Width : as customers' demand

Number of sets (layers) : as customers' demand

Product features:

Our highly flexible braided copper tapes consist of annealed uncoated or tinned copper wires. The ends of the cable have seamless contact areas which have been pressed on under extreme pressure (not soldered). By using this production method material of same analysis and same conductivity (E-Cu tubing and stranded wire)is being connected without using foreign materials like tin or welding additions. This creates a flexible component with very low resistance. Upon request, also can be insulated with Heat shrinkable tube/PVC/silicone or another insulating material. For use in galvanizing equipment, we also provide liquid resistant versions. We produce as customer's requirement . The values shown on the above page refer to individual cables and are independent standard values. They are manufactured as flatten rolled tubes. The construction of the braids are so selected that a maximum of flexibility and a optimal finishing is guaranteed.

Lab Test:

Advantages:

1. Easy processing and forming

2. High load flow

3. Easy installation

4. Excellent electrical conductivity.

5. High bonding strength.

6. Available for bending, drilling, stamping etc.

7. Pure T2 copper

8. Form E, C/O is available.

9. Good flexibility ------copper braid provides multi axis connection and transition. Tackling opposing alignments trough 180 degrees can be easily overcome with this type of design.

10. Long term life cycle.

11. Cost: extraordinary cost/performance ratio.

12. Absorbing movements and vibrations.

Why Choose Us:

Advanced equipment: High-quality equipment imported from Japan and Taiwan, as well as first-class materials at home and abroad, using materials that meet UL standards, and strictly comply with RoHS environmental protection requirements,which not only improves the efficiency and productivity, but also reduces the waste of manpower and raw materials, and controls the product quality more finely.

Good quality control: All products are 100% tested before delivery, including circuit test, tensile test, temperature and pressure resistance test, etc. We have passed the international authoritative IATF 16949 quality system certification and safety system certification.

Firm concept: We always put product quality first. XINCHENG employees take "quality, service, innovation, and sustainability" as their concept, and use thoughtful service and continuous innovation to meet customers' current and future growing needs and expectations.

FAQ

1. Q: Are you factory or trading company?

A: We are factory.

2. Q: Where is your factory located?

A: We are located in the TIANJIN city, near the BEIJING city , China.

3. Q: Can I get sample before making order?

A: We can send you free samples if you tell us the model and size you need, or you send us your drawing.

4. Q: Do you accept small order or trial order?

A: Small order and trial order are acceptable.

5. Q: How long can I get a sample?

A: we have samples in stock, we can send it in one day.

6. Q: How do you inspect goods?

A: We have inspection department. All goods will be inspected before packing.

7. Q: What's your payment term?

A: For small order, we suggest 100% before production to save time and bank charge. For bulk order, 30%TT deposit 70%TT before delivery.

Packaging & Delivery

Packaging Details:

Inner packing: plastic bag /inner Carton + Plywood Pallets or plywood case/ fumigated wood case

Outer Packing: Plywood case/export carton with pallets/ According to customers' requirement

Delivery Time: About 7-15 days.

Please Contact Us

Miss: lydia

Mob: 86-13752439076 Fax: 86-22-60863016

Place of Origin: China Brand Name: XIN CHENG

Type: Braid

Application: grounding, for electrical connection, flexible connected wires, Electrostatic shielding, power, etc.

Material: C11000 copper, copper content more than 99.9% Conductor Type: Solid

Insulation Material: none Feature: pure copper wire braided

plated: none or Tinned or nickel Cross section: 1.5-400mm2

Single wire diameter: 0.05-0.3mm Length: as customers' demand

Width : as customers' demand Number of sets (layers) : as customers' demand

Certificate: ISO9001; RoHS Standard: TZ/TZX(JB2572-79)

Product Description:

Copper Braided Grounding Strap is made by braiding a number of spindles (13,16,24,36,40,48,64,96) of best quality round copper wires (0.05,0.10,0.12,0.15,0.19,0.20,0.25mm) or soft tinned wires (0.05,0.10,0.12,0.15,0.19,0.20mm) to become single layer of multilayer type. It is used for the flexible conductor of electric installation, switch gear, electric furnace, storage battery, etc.

If you have any other special specifications, please provide drawings or samples, our company can customize the products according to your request.

The commonly used Single wire diameter: 0.05mm, 0.07mm, 0.10mm, 0.12mm, 0.127mm, 0.15mm, 0.2mm, 0.25mm, 0.254mm, 0.3mm etc.

Copper braided tape Material: red copper Surface treatment: tin/silver/nickel plating according to technical requirements Application: New energy electric vehicle battery copper soft connection is suitable for battery conduction, automobile, aerospace, mechanical and electrical equipment, medical equipment and other conductive fields. Product features: fire - proof, electric - conduction, pressure - proof, corrosion - proof, etc.

The tinned copper braided mesh tube is braided by multiple strands of tinned copper wire with a diameter of 0.05-0.30mm. It has flexibility, wear resistance, anti-electromagnetic interference of wires, and electrical conductivity, which can tighten wires of various irregular shapes. It can also remain soft in a wide temperature range, and its unique mesh shape has good heat dissipation.

Copper braid tape and flexible busbar connectors with termination for switchgear and control panels such as power interconnections, earth bonding leads, earth braid assemblies and flexible busbar assemblies for high current application

Application:

Copper braided tape is also widely used in transformer installation, soft connection of high and low voltage switchgear, vacuum electrical appliances, closed bus duct, generator and bus, rectifier equipment, rectifier cabinet and disconnector, automobile, electric locomotive, industrial electric furnace, mining explosion-proof electrical appliances, generator set, carbon brush wire and connection between buses. It can improve the conductivity, adjust the equipment installation error, and play the role of (shock absorption) work compensation, convenient test and equipment maintenance.

Technical Performance:

Technical Performance: | Wire diameter | 0.15mm |

| DC resistivity (20 °C, copper braided wire ) | less than 0.022 Ω.Mm2/m |

| DC resistivity (20 °C, tinned copper braided wire ) | less than 0.0234Ω.Mm2/m |

| 100sqmm Power Shunt = 400amps |

| 240sqmm Power Shunt = 650amps |

| 300sqmm Power Shunt = 760amps |

| 500sqmm Power Shunt = 1100amps |

| 600sqmm Power Shunt = 1250amps |

Specifications:

| Cross section(mm2) | Number of strands X number of pieces X number of sets (layers)/diameter of single wire | Width | Thickness | Meters/roll | Weight (KG) |

| 2.5 1 layer | 24*6*1/0.15 | 6 | 1 | 100 | 0.025 |

| 4 1 layer | 24*10*1/0.15 | 8 | 1 | 100 | 0.040 |

| 6 1 layer | 32*10*1/0.16 | 12 | 1 | 100 | 0.060 |

| 10 1 layer | 48*12*1/0.15 | 18 | 1.3 | 100 | 0.100 |

| 16 1 layer | 48*20*1/0.15 | 25 | 2 | 100 | 0.160 |

| 25 1 layer | 48*30*1/0.15 | 30 | 2 | 100 | 0.250 |

| 35 2 layers | 48*20*2/0.15 | 25 | 3 | 100 | 0.350 |

| 50 2 layers | 48*30*2/0.15 | 31 | 4 | 100 | 0.500 |

| 70 3 layers | 48*30*3/0.15 | 32 | 5 | 50 | 0.700 |

| 100 4 layers | 48*30*4/0.15 | 33 | 6 | 50 | 1.000 |

| 120 5 layers | 48*30*5/0.15 | 34 | 7 | 50 | 1.200 |

| 150 6 layers | 48*30*6/0.15 | 38 | 8 | 50 | 1.500 |

| 185 5 layers | 64*30*5/0.15 | 50 | 10 | 50 | 1.850 |

| 240 4 layers | 80*30*4/0.15 | 60 | 10 | 50 | 2.400 |

Single wire diameter: 0.05-0.3mm,Length: as customers' demand

Width : as customers' demand

Number of sets (layers) : as customers' demand

Product features:

Our highly flexible braided copper tapes consist of annealed uncoated or tinned copper wires. The ends of the cable have seamless contact areas which have been pressed on under extreme pressure (not soldered). By using this production method material of same analysis and same conductivity (E-Cu tubing and stranded wire)is being connected without using foreign materials like tin or welding additions. This creates a flexible component with very low resistance. Upon request, also can be insulated with Heat shrinkable tube/PVC/silicone or another insulating material. For use in galvanizing equipment, we also provide liquid resistant versions. We produce as customer's requirement . The values shown on the above page refer to individual cables and are independent standard values. They are manufactured as flatten rolled tubes. The construction of the braids are so selected that a maximum of flexibility and a optimal finishing is guaranteed.

Lab Test:

| Test Program | Tester | Standard | Test Result |

| Conductivity Test | Conductivity tester | upon your request | √ |

| Fatigue test | Fatigue tester | upon your request | √ |

| Voltage withstand test | Voltage withstand tester | upon your request | √ |

| DC resistance test | DC resistance tester | upon your request | √ |

| Salt spray test | Salt spray tester | upon your request | √ |

| Pull test | Pull tester | upon your request | √ |

| Insulated resistance | Insulated resistance tester | upon your request | √ |

Advantages:

1. Easy processing and forming

2. High load flow

3. Easy installation

4. Excellent electrical conductivity.

5. High bonding strength.

6. Available for bending, drilling, stamping etc.

7. Pure T2 copper

8. Form E, C/O is available.

9. Good flexibility ------copper braid provides multi axis connection and transition. Tackling opposing alignments trough 180 degrees can be easily overcome with this type of design.

10. Long term life cycle.

11. Cost: extraordinary cost/performance ratio.

12. Absorbing movements and vibrations.

Why Choose Us:

Advanced equipment: High-quality equipment imported from Japan and Taiwan, as well as first-class materials at home and abroad, using materials that meet UL standards, and strictly comply with RoHS environmental protection requirements,which not only improves the efficiency and productivity, but also reduces the waste of manpower and raw materials, and controls the product quality more finely.

Good quality control: All products are 100% tested before delivery, including circuit test, tensile test, temperature and pressure resistance test, etc. We have passed the international authoritative IATF 16949 quality system certification and safety system certification.

Firm concept: We always put product quality first. XINCHENG employees take "quality, service, innovation, and sustainability" as their concept, and use thoughtful service and continuous innovation to meet customers' current and future growing needs and expectations.

FAQ

1. Q: Are you factory or trading company?

A: We are factory.

2. Q: Where is your factory located?

A: We are located in the TIANJIN city, near the BEIJING city , China.

3. Q: Can I get sample before making order?

A: We can send you free samples if you tell us the model and size you need, or you send us your drawing.

4. Q: Do you accept small order or trial order?

A: Small order and trial order are acceptable.

5. Q: How long can I get a sample?

A: we have samples in stock, we can send it in one day.

6. Q: How do you inspect goods?

A: We have inspection department. All goods will be inspected before packing.

7. Q: What's your payment term?

A: For small order, we suggest 100% before production to save time and bank charge. For bulk order, 30%TT deposit 70%TT before delivery.

Packaging & Delivery

Packaging Details:

Inner packing: plastic bag /inner Carton + Plywood Pallets or plywood case/ fumigated wood case

Outer Packing: Plywood case/export carton with pallets/ According to customers' requirement

Delivery Time: About 7-15 days.

Please Contact Us

Miss: lydia

Mob: 86-13752439076 Fax: 86-22-60863016