Basic Info.

Model NO.

A-1

Lead Time

5-10 Days

Packing

as Per Customer′s Request

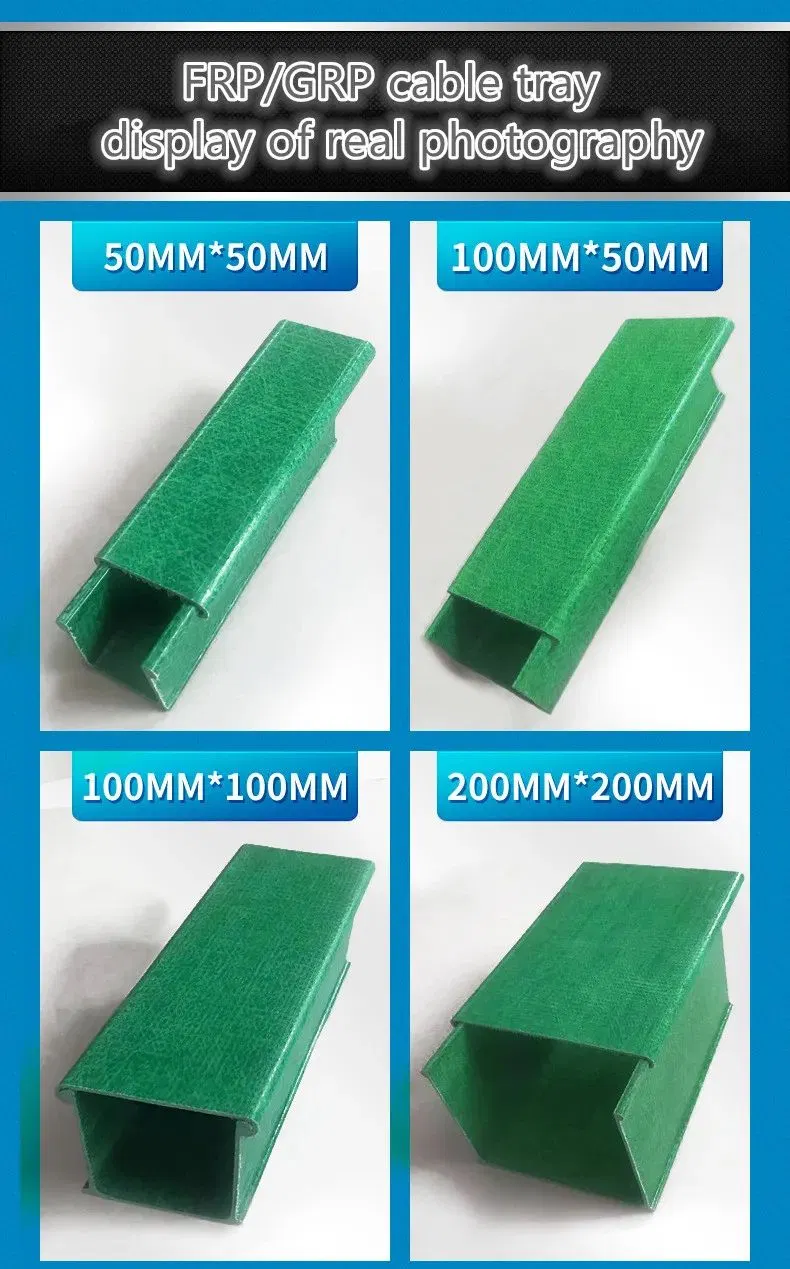

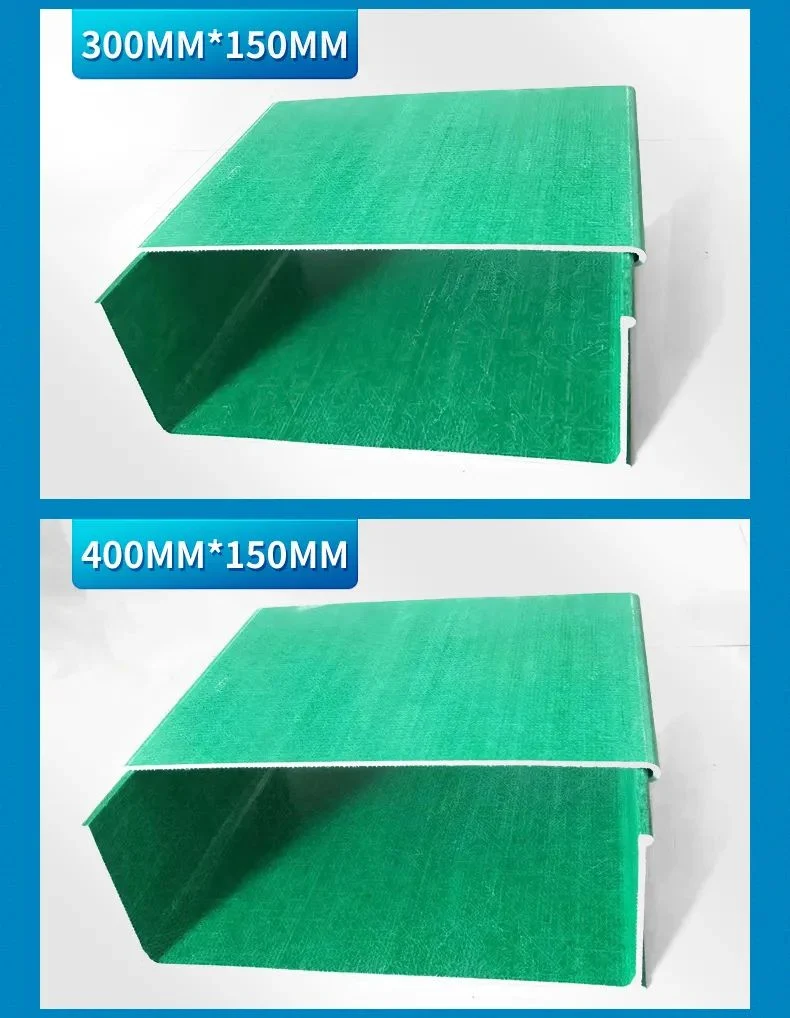

Size

Customized

Keywords

FRP Cable Tray/Fiberglass Cable Tray

Transport Package

by Sea, by Truck, by Train, by Air

Specification

300mm*200mm*4.5mm

Trademark

solucent FRP Cable Tray

Origin

China

HS Code

39259000

Production Capacity

50 Million Meters

Product Description

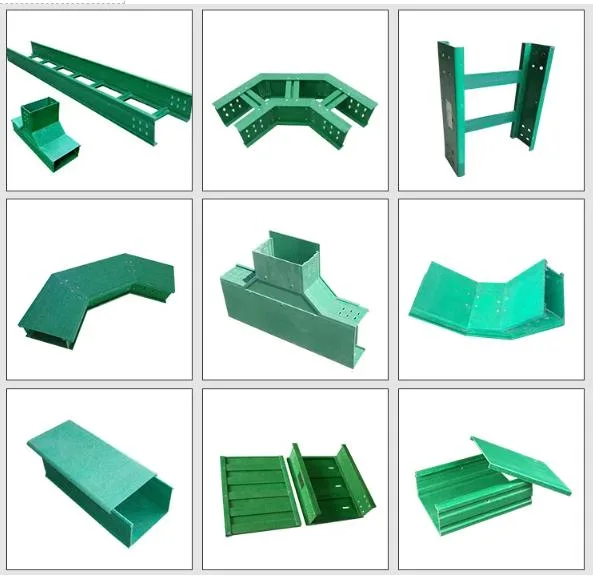

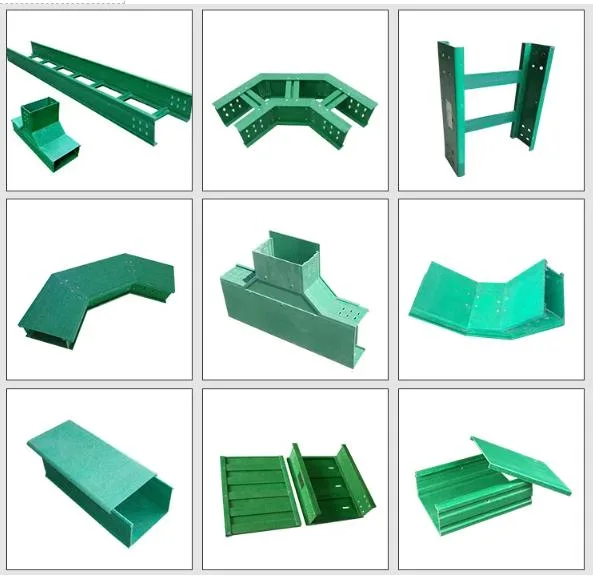

Fiber glass reinforced plastic ladder rack cable tray FRP cable tray Ladder

Fiberglass reinforced plastic (FRP) anti-corrosion cable bridge or tray is made of glass fiber, epoxy resin and other special materials, it has reasonable mechanical structure, light weight,high strength, strong corrosion resistance, flame retardance, aging resistance and good insulation performance, it can be used in a large range of temperature and the environments of high humidity, heavy acid and or heavy alkali. the service life is 5-6 times of the steel bridge, the installation distance of one ton of FRP cable bridge or tray is 1.5 times of the steel bridge with same specification and same weight.FRP cable bridge can be overhead laying; erected under the beam or floor slab,can be fixed laterally by indoor and outdoor walls, posts, tunnels, cable trench walls., can also be installed in the open air.

specification

note: Customized size is supported.

Application

Cable tray system is made up of cable tray, cable tray bend, bracket, corbel, accessories etc. It used to support the cable in the

process of installation and laying. Cable tray is divided into solid trough & cable trunking, cable ladder, ventilated &

perforated trough, large span type etc.

Cable tray apply to construction industry, chemical factory, power projects etc widely.

FRP cable tray has high mechanical strength. It has both the rigidity of metal cable tray and toughness of FRP cable tray, such as

good corrosion resistance, strong ageing resistance, beautiful modelling, easy installation, long service life. Epoxy resin and

epoxy resin composite cable tray is suited for strong corrosion environment, large span and heavy load conditions.

Certificates

FAQ

Fiberglass reinforced plastic (FRP) anti-corrosion cable bridge or tray is made of glass fiber, epoxy resin and other special materials, it has reasonable mechanical structure, light weight,high strength, strong corrosion resistance, flame retardance, aging resistance and good insulation performance, it can be used in a large range of temperature and the environments of high humidity, heavy acid and or heavy alkali. the service life is 5-6 times of the steel bridge, the installation distance of one ton of FRP cable bridge or tray is 1.5 times of the steel bridge with same specification and same weight.FRP cable bridge can be overhead laying; erected under the beam or floor slab,can be fixed laterally by indoor and outdoor walls, posts, tunnels, cable trench walls., can also be installed in the open air.

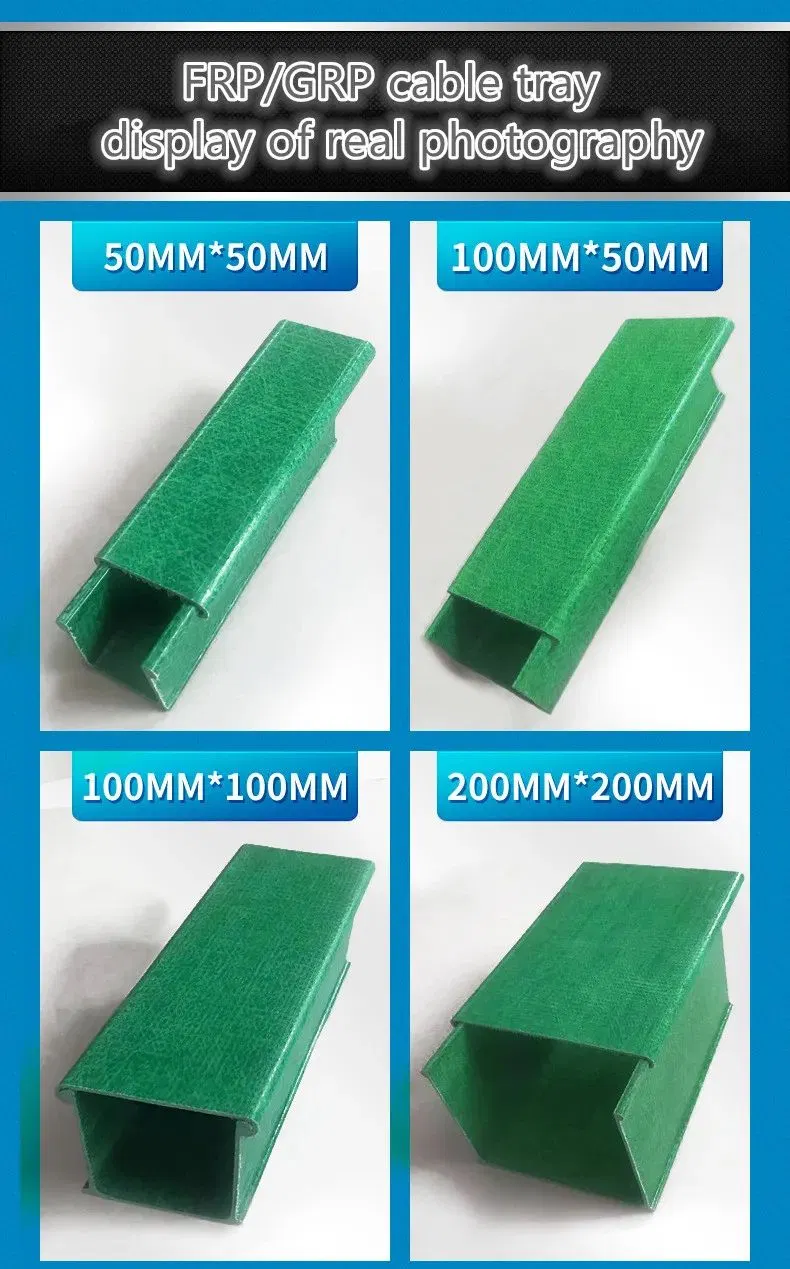

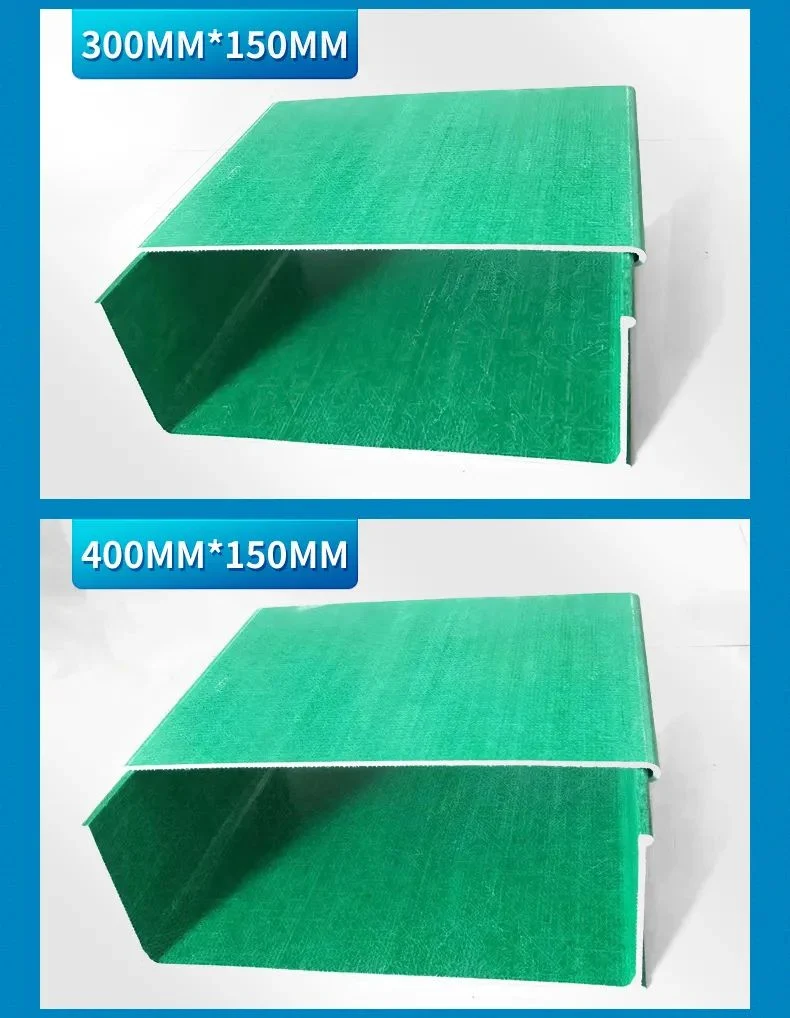

specification

| B(mm) | H(mm) | TH(mm) |

| 100 | 50 | 3 |

| 100 | 3 | |

| 150 | 100 | 3.5 |

| 150 | 3.5 | |

| 200 | 100 | 4 |

| 150 | 4 | |

| 200 | 4 | |

| 300 | 100 | 4 |

| 150 | 4.5 | |

| 200 | 4.5 | |

| 400 | 100 | 4.5 |

| 150 | 5 | |

| 200 | 5.5 | |

| 500 | 100 | 5.5 |

| 150 | 6 | |

| 200 | 6.5 | |

| 600 | 100 | 6.5 |

| 150 | 7 | |

| 200 | 7.5 | |

| 800 | 100 | 7 |

| 150 | 7.5 | |

| 200 | 8 |

Application

Cable tray system is made up of cable tray, cable tray bend, bracket, corbel, accessories etc. It used to support the cable in the

process of installation and laying. Cable tray is divided into solid trough & cable trunking, cable ladder, ventilated &

perforated trough, large span type etc.

Cable tray apply to construction industry, chemical factory, power projects etc widely.

FRP cable tray has high mechanical strength. It has both the rigidity of metal cable tray and toughness of FRP cable tray, such as

good corrosion resistance, strong ageing resistance, beautiful modelling, easy installation, long service life. Epoxy resin and

epoxy resin composite cable tray is suited for strong corrosion environment, large span and heavy load conditions.

Certificates

FAQ

Q1 : Are you trading company or factory?

We are an export trading company, but in domestic, we have a factory that is over 12 years old.

Q2: How about the delivery time?

Usually within 7-10 days, Custom or peak season, may need longer time, about 20 days.