- Overview

- Product Description

Basic Info.

Packaging & Delivery

Product Description

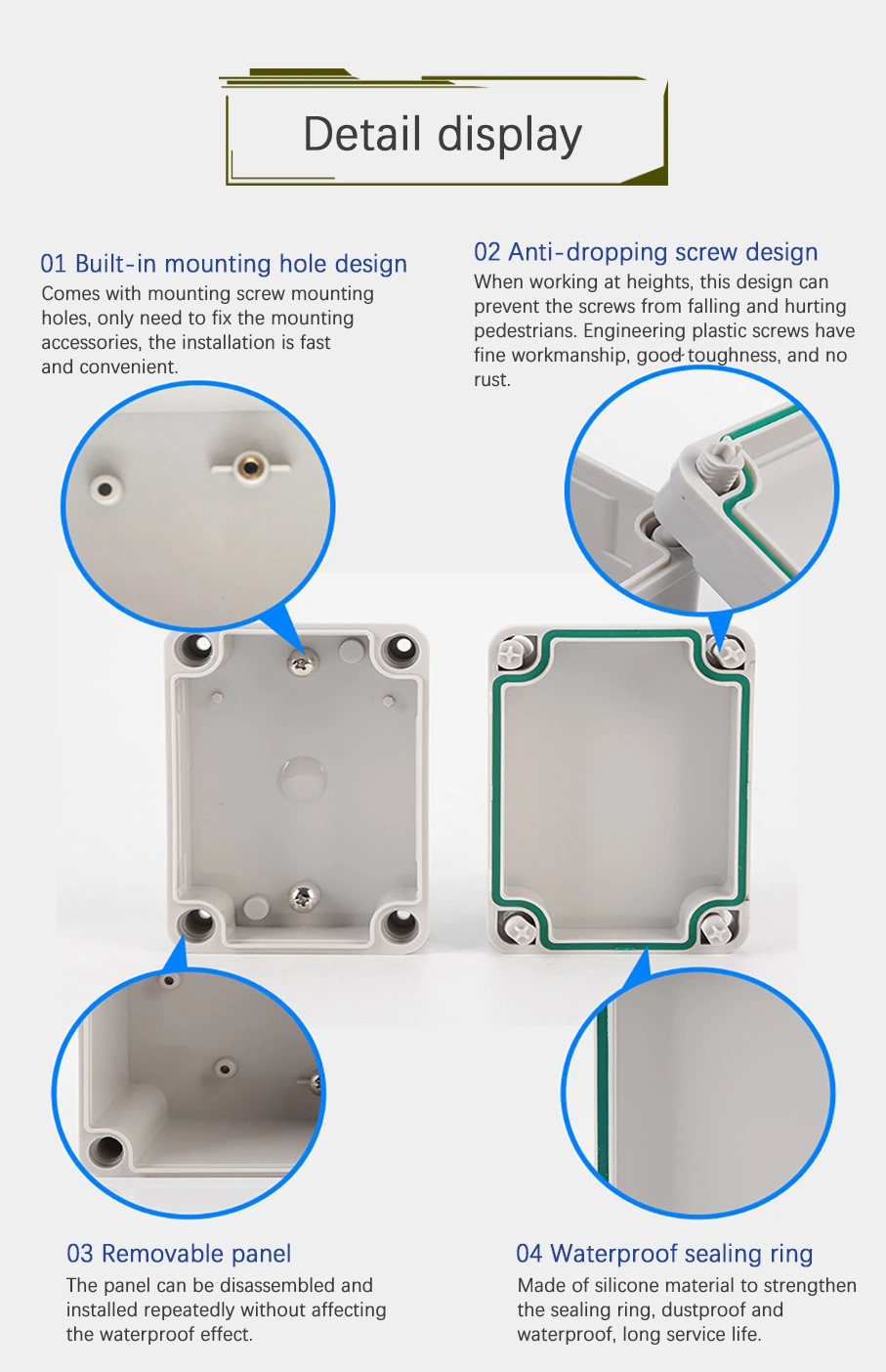

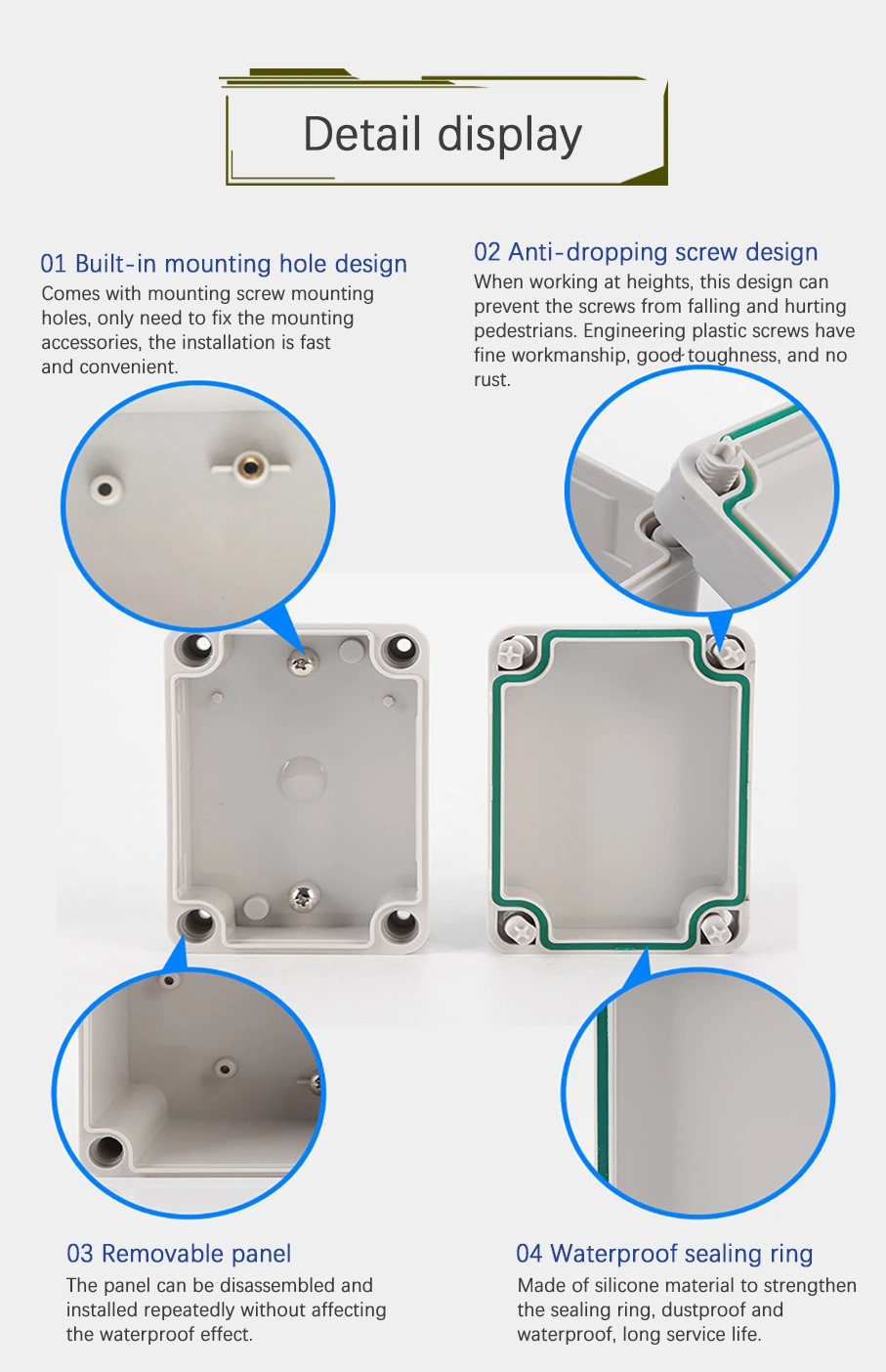

Flame Retardant Plastic Enclosure Junction Box with Terminal Blocks

| Mold Material | Aluminum,45#, P20, H13, 718, 1.2344, 1.2738 and so on |

| Plastic Material | PC/ABS, ABS, PC, PVC, PA66, POM or other you want |

| silicon rubber Material | NR, NBR, SBR, EPDM, IIR, CR, SILICONE, VITON,etc |

| Plastic Surface finish | Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc |

| Drawing format | IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc.. |

| The Way of Color Contrast for Plastic | RAL PANTONE |

| Certificated | ISO 9001:2015 Certificated, SGS Certificated |

| Service Project | To provide production design, production and technical service, mould development and processing, product assembly and packaging,etc |

1. Professional OEM/ ODM service, custom manufacturing.

2. The material is ABS.

3. Material Characteristics: Strong impact strength; Good electrical performance; Anti-stamping, high heat resistance, flame retardant; Surface chrome plating, painting treatment can be done and etc.

4. Factory price, one stop solution, prompt delivery, after-service.

Rapid tooling

Fast and cost-effective process to create aluminum or steel injection molds for quick turn injection molding. Ideal for rapid prototyping needs or validating product concept for production.

Overmolding

Overmolding is a unique injection molding process that combines two or more components together. It is the best practice for the plastic manufacturing of multi-color and multi-layers products.

Insert molding

Insert molding is a custom injection molding process that encapsulates components in a plastic part. It is most commonly used for prototype injection molding designs with threads and holes.

Liquid Silicone Rubber injection molding

Liquid silicone rubber (LSR) is a flexible prototype injection molding process that produces elastic, durable parts. Get custom prototypes and production parts from 15 days.

| Item | Description |

| 1.Mould material | P20,718H,45#,STAVAX ESR S136,H13,2316,2083,2344 |

| 2.Hardness of steel | vacuum quenching, nitride, HRC41-47, HRC46-50, HRC60 |

| 3.Inserts / Slider steel | H13 (DIN.1.2344),tempered with HRC46-50 |

| 4.Mould spare parts | H13 (Din 1.2344),tempered with HRC40-45,nitrited with HRC60-62 |

| 5.Mould base | LKM,HASCO |

| 6.Mould cavity | Single / Multi |

| 7.Runner system | Hot / Cold |

| 8.CAD centre for data formats | IGES,X_T,STP & DWG,etc |

| 9.Plastic material | ABS,PC,PE,PP,PS. |

| 10.Mould life | 80000- more than 1000000 |

| 11.Delivery time | 4-8 weeks |

| 12.Terms of payment | T/T, Paypal, Western Union and so on |

Strict inspection we do during operation

Strict inspection we do during operation

Experienced QC testers to check the products dimension, surface and performance according to drawings specification.

Experienced IQC to check the dimensions and surface of the incoming material.

Experienced PQC to inspect full-course during the processing.

Experienced FQC to inspect all the plating products from outsides and make the 100% inspection before the shipments.

Quality sample will be provided for your testing before production according to ISO 9001: 2015.

We are pleased to service you with excellent quality, reasonable cost and grow with you together.

Our Services

1.Product Design,Structural Optimization,Process Optimization.

2.Mold Making,Plastic Molding Parts,Casting Parts,Machining Part.

3.Manage Project,Control The Delivery and Quality of Products.

4.Arranging the Transportation,Customs Clearance and other Matters for You. Advantages:

Advantages:

1. Competitive price.

2. Strict quality control system.

3. Quick mold making and delivery.

4. Advanced equipment, excellent R&D teams.

5. Professional technicians and rich experienced workers.

below approach!