- Overview

- Product Description

Basic Info.

Model NO.

WF-JF

Usage

Electrical Appliance, Motor, Machinery, Car, Cable

Material

Aluminum Alloy

Type

Bolt Type

Item

Cable Clamp

Export Markets

Global

Shipping Port

Qingdao

Place of Origin

China

Transport

by Sea or Air

Packing

Wooden Cases or Carton

Weight

Customized

Sample

7 Days Ready

Processing

as Per Your Drawing

Materials

as Per Request

After-Sale Service

Definetly

Certificate of Origin

as Per Request

Transport Package

Plywood Box

Specification

As your requirement

Trademark

jufeng

Origin

Weifang City, Shandong Province, China

HS Code

7326199000

Production Capacity

10000PCS/Month

Packaging & Delivery

Package Size

40.00cm * 30.00cm * 20.00cm

Package Gross Weight

50.000kg

Product Description

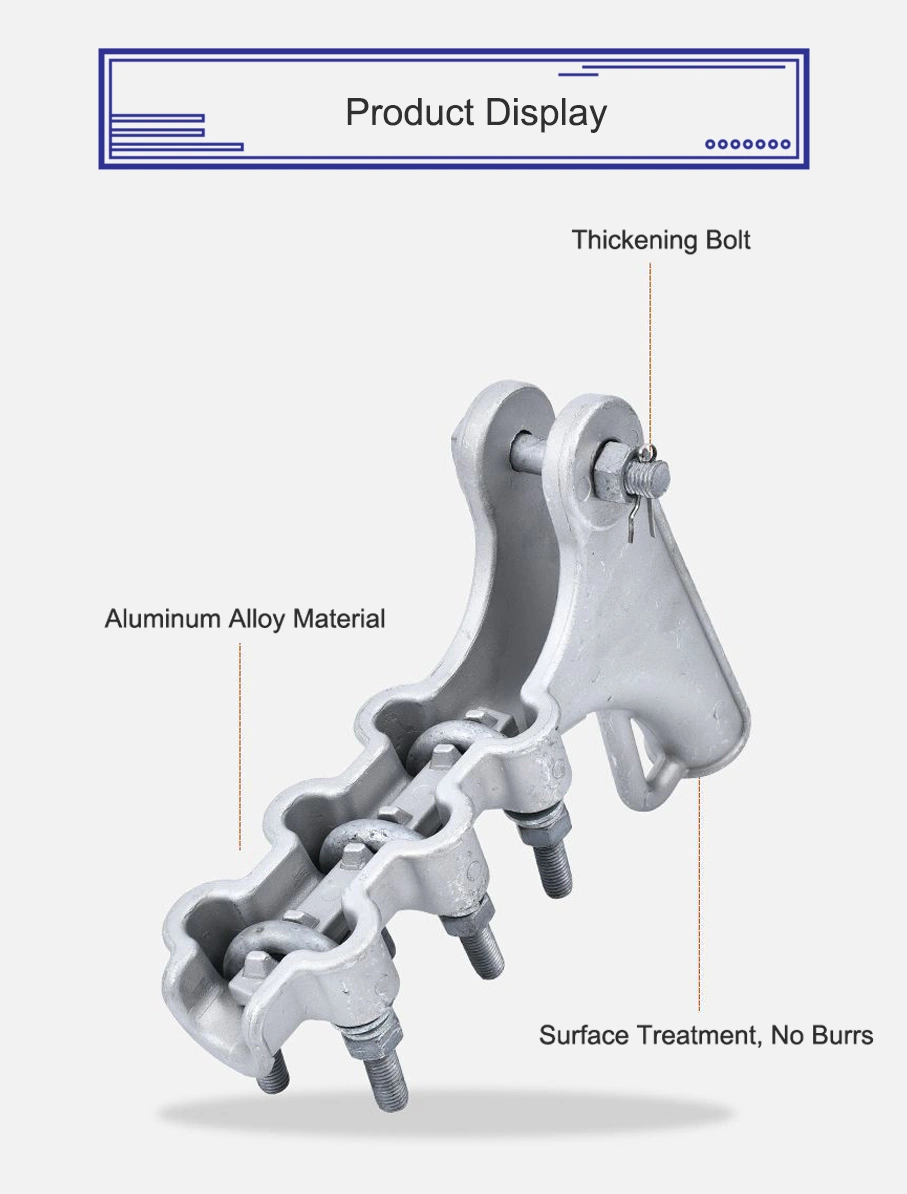

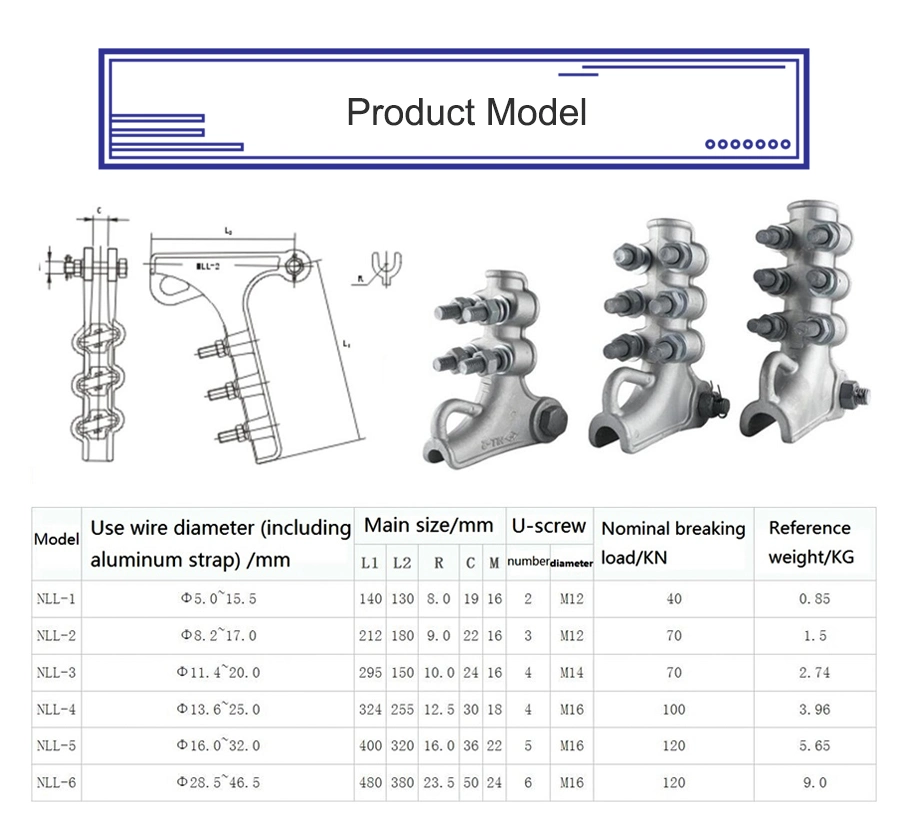

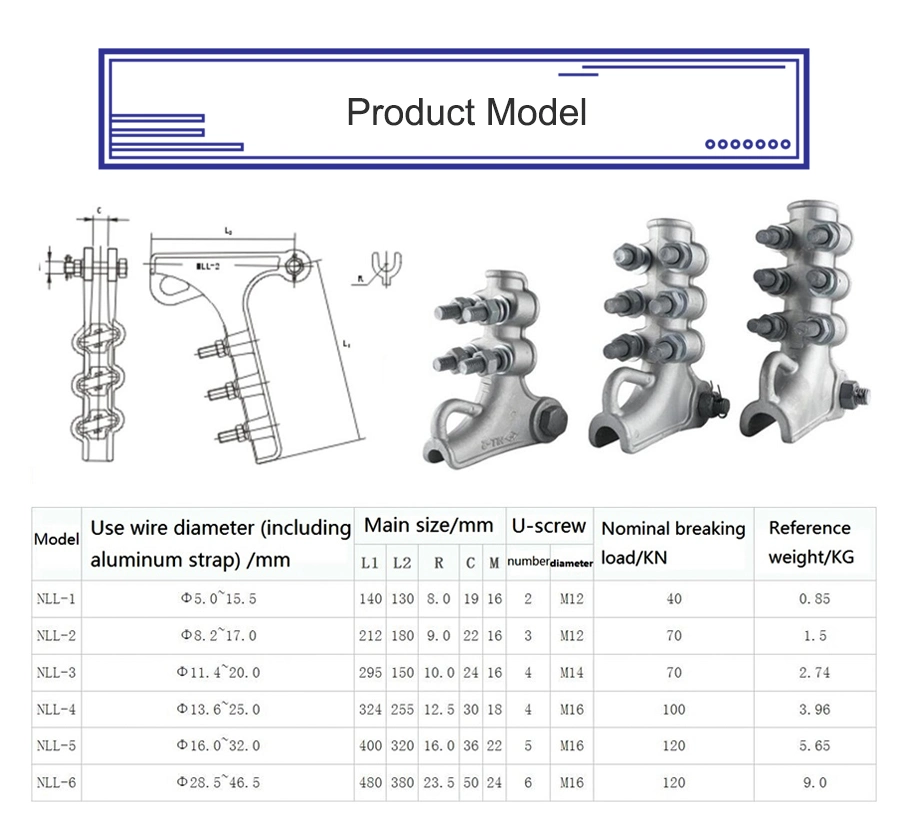

Hot-Selling Electric Power Fitting Casting Wedge Type Dead End Strain Tension Clamp

The products are widely used in transmission and distribution lines of electrical energy, optical cable lines and

high-speed railway lines. Bolt type aluminum alloy tension clamp is used for non load-bearing connection fittings

of distribution system, connection of aluminum strand or steel core or aluminum strand, connection between aluminum strand and copper strand, and connection between copper strand in non seriously polluted areas.

It is designed for aerial lines up to 30kV.

It is designed for aerial lines up to 30kV.

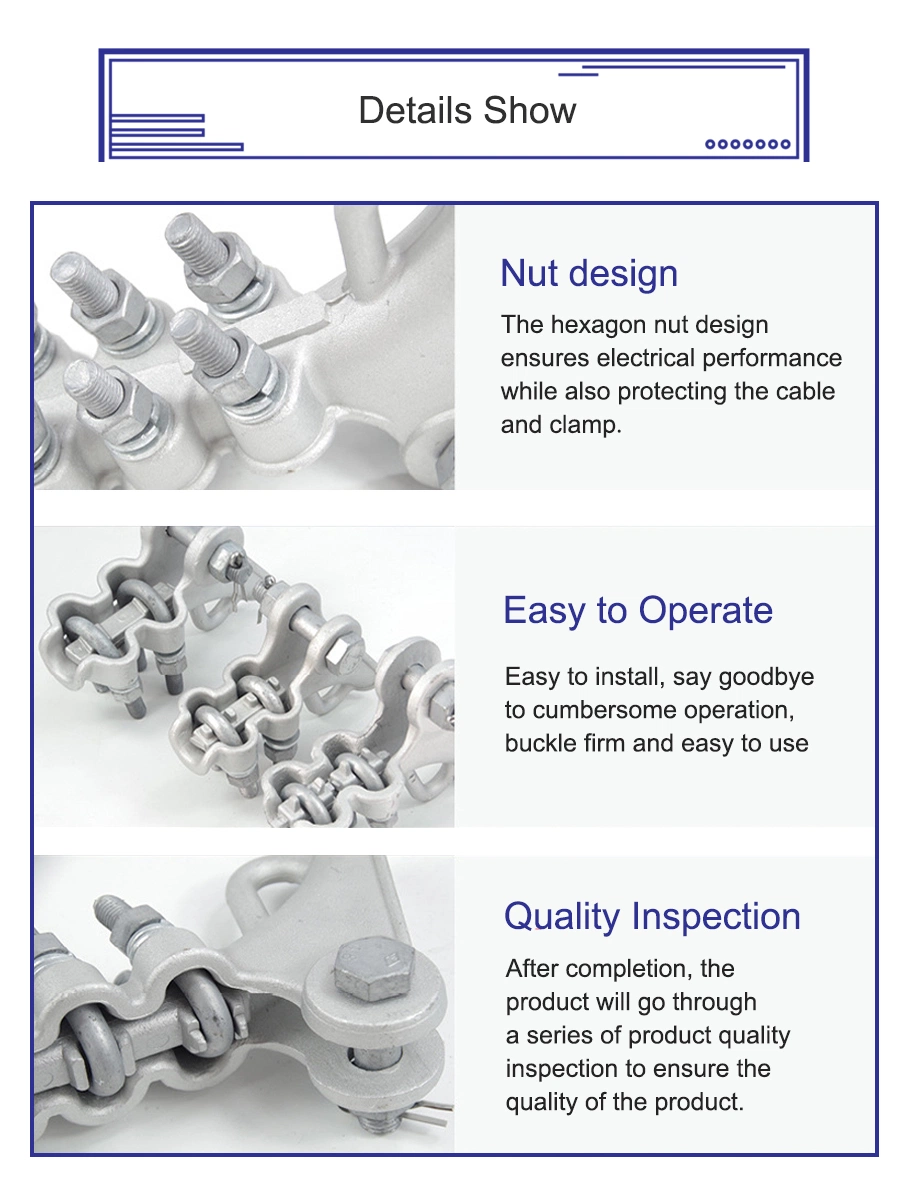

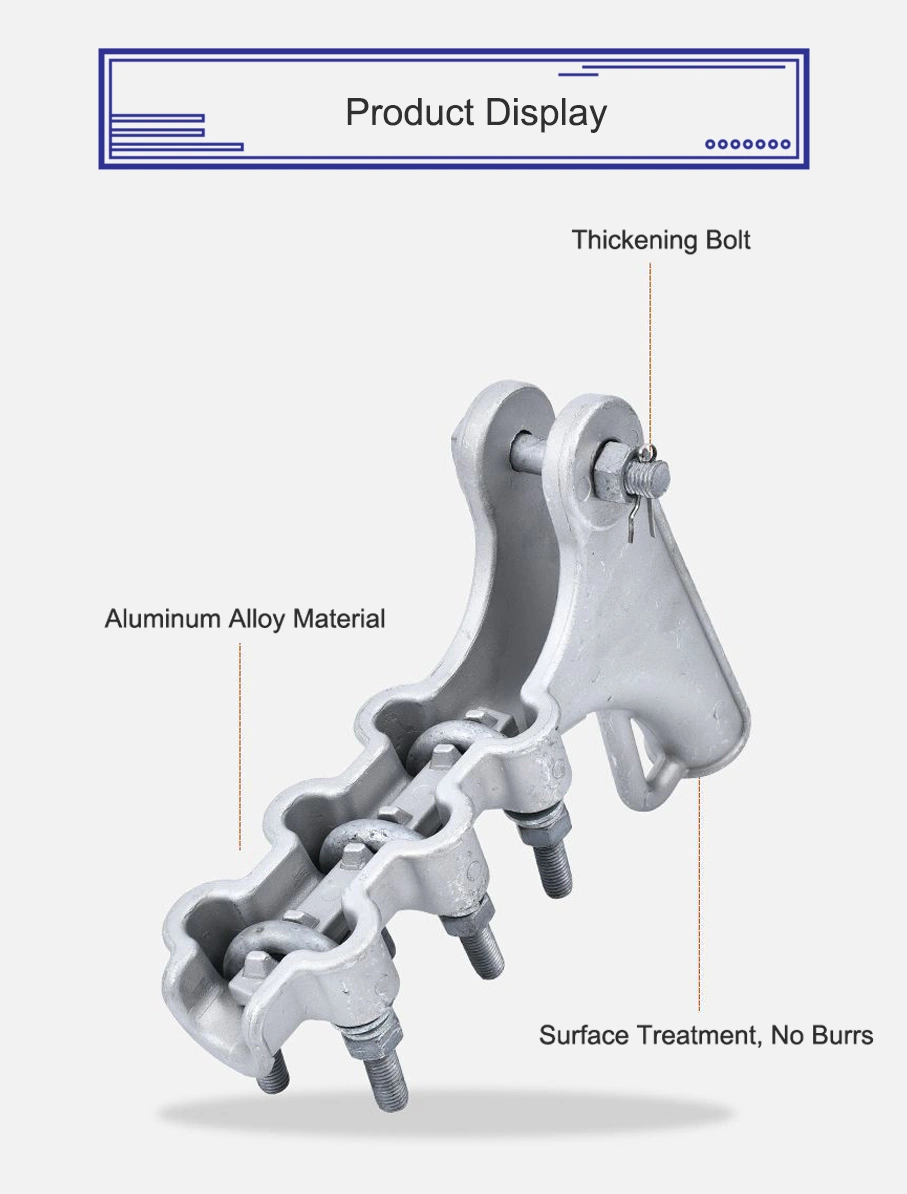

1) Be suitable for fixing insulated aluminum conductor or naked aluminum conductor on the rotate angle or insulator of terminal strain pole, to fix and tighten the aerial conductor.

2) Material: body, keeper - aluminum alloy, split pin - stainless steel, others - hot-dip galvanized steel.

3) Grip strength of the clamp is more than 95% break strength of the conductor.

4) Insulation cover and strain clamp used together for insulation protection

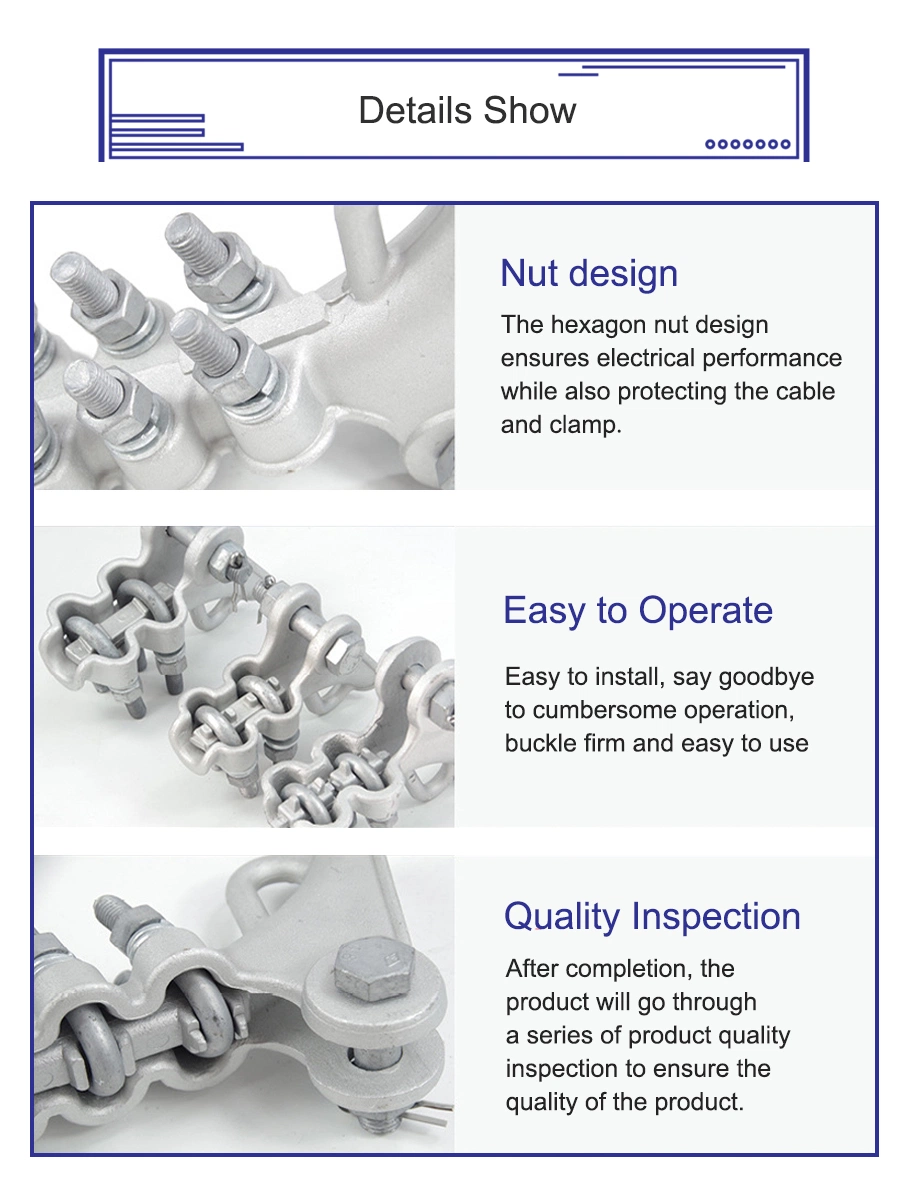

Structural features:

1. The clamp body is made of high-strength aluminum alloy;

2. Smooth appearance and long service life;

3. Easy to install and use with spanners

4. It has no power loss and is an energy-saving certified product.

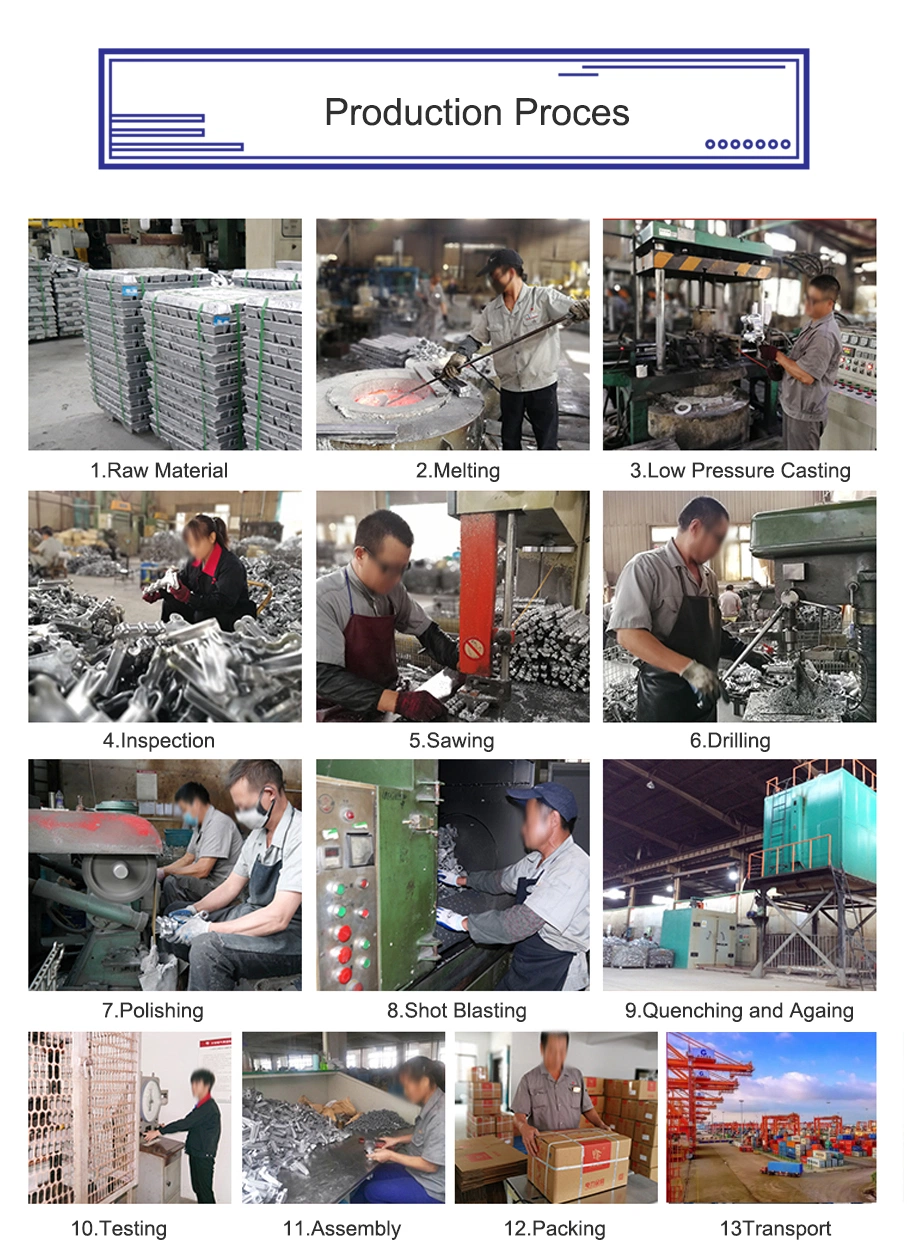

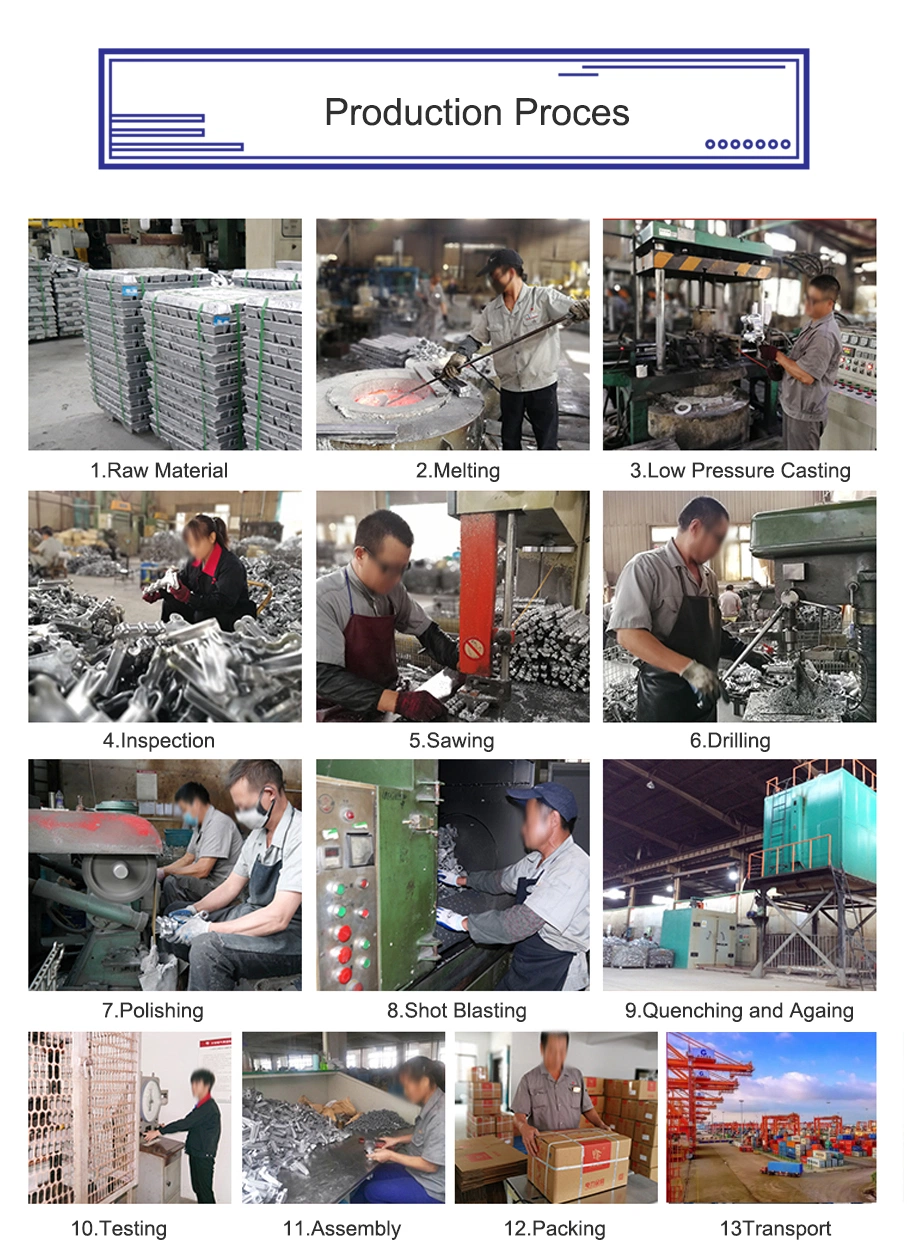

OUR PRODUCING PROCESS:

OUR PRODUCING PROCESS:

1. Tooling (Mold) design and Manufacture.

2. Manufacture the parts according to the Stamping Machine.

3. Riveting, Welding or Screw tap according to Customer's require.

4. After finish manufacture process we will test the parts by the Image measurement instrument, Caliper,

Angel Gage etc.

5. After make sure all the dimension can reach customer's require, we will make the surface treatment process.

6. After finish surface treatment we will testing all the parts by worker so that we can make sure the parts which

we sell is 100% qualified.

7. After finish testing we will pack the parts by Vacuum Package Machine.

high-speed railway lines. Bolt type aluminum alloy tension clamp is used for non load-bearing connection fittings

of distribution system, connection of aluminum strand or steel core or aluminum strand, connection between aluminum strand and copper strand, and connection between copper strand in non seriously polluted areas.

It is designed for aerial lines up to 30kV.

It is designed for aerial lines up to 30kV.1) Be suitable for fixing insulated aluminum conductor or naked aluminum conductor on the rotate angle or insulator of terminal strain pole, to fix and tighten the aerial conductor.

2) Material: body, keeper - aluminum alloy, split pin - stainless steel, others - hot-dip galvanized steel.

3) Grip strength of the clamp is more than 95% break strength of the conductor.

4) Insulation cover and strain clamp used together for insulation protection

| Structure: | Tension clamp |

| Material: | Aluminium |

| Usage: | Heavy Duty |

| Standard: | IEC61284 |

Structural features:

1. The clamp body is made of high-strength aluminum alloy;

2. Smooth appearance and long service life;

3. Easy to install and use with spanners

4. It has no power loss and is an energy-saving certified product.

OUR PRODUCING PROCESS:

OUR PRODUCING PROCESS:1. Tooling (Mold) design and Manufacture.

2. Manufacture the parts according to the Stamping Machine.

3. Riveting, Welding or Screw tap according to Customer's require.

4. After finish manufacture process we will test the parts by the Image measurement instrument, Caliper,

Angel Gage etc.

5. After make sure all the dimension can reach customer's require, we will make the surface treatment process.

6. After finish surface treatment we will testing all the parts by worker so that we can make sure the parts which

we sell is 100% qualified.

7. After finish testing we will pack the parts by Vacuum Package Machine.